Low cost MCC solution

Retrofit and new build

24x7 thermal monitoring

Very simple to install

Continuous Thermal Monitoring for MCCs

Motor Control Centers (MCCs) are prone to failures from loose or compromised connections, often at the rear of the bucket or in-drawer joints, which are impossible to inspect without de-energizing. Traditional maintenance methods rarely catch these problems early. Many facilities only discover thermal faults when damage is severe and repairs become expensive. Continuous Thermal Monitoring (CTM) for Motor Control Centers provides real-time visibility into MCC health, enabling proactive intervention before failures disrupt operations.

Transform MCCs into smart assets

24/7 all-year-round protection for critical electrical assets in harsh industrial environments

Avoid costly unplanned downtime

Prevent MCC failures that can stop production and lead to outages averaging 7+ hours per incident

Increase personnel and asset safety

Reduce interaction with faulty MCCs and mitigate arc flash risks for personnel in high-risk zones

Boost asset and operational reliability

Detect loose connections, overheating, and ageing components before they cause catastrophic shutdowns

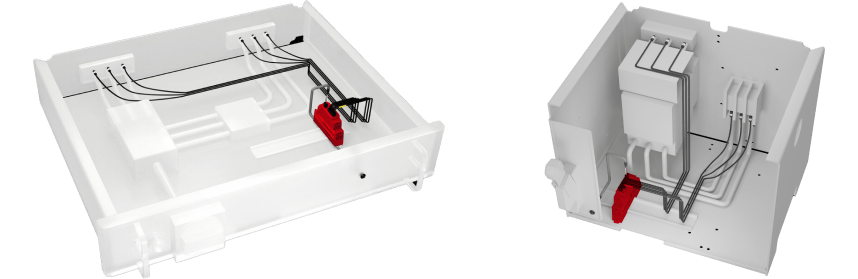

MCC Drawer

Exertherm MCC Solution - Drawer

MCC Bucket

Exertherm MCC Solution - Bucket

How Continuous Thermal Monitoring (CTM) transformed reliability in a 24/7 mining operation

Energy conglomerate replaced periodic thermography with always‑on proactive monitoring

Frequently asked questions

From the essentials to the more advanced, these are some of the questions we’re asked most often. Get in touch to learn more about MCC Monitoring Solution.

We never had a problem, why should we monitor?

-1.png?width=24&height=24&name=Vector%20(2)-1.png)

Motor Control Centers (MCC) are known to be prone to failure caused by loose or compromised connections. The joints most susceptible to faults are typically at the rear of the MCC bucket/in-drawer, and impossible to access for inspection without de-energizing (especially in-drawers). Many facilities don’t realize they have thermal issues until it’s too late, and damage has already occurred, which can be inconvenient and costly.

Can thermal sensors be retrofitted to existing motor control centers?

-1.png?width=24&height=24&name=Vector%20(2)-1.png)

Yes. Exertherm's MCC solution can be used for both new build motor control centers as well as retrofit existing assets.

Why can’t we rely on periodic inspection?

-1.png?width=24&height=24&name=Vector%20(2)-1.png)

Annual thermography inspections are typically conducted annually, which is less than 1% of a monitoring cycle. This approach relies on luck to detect a failure during an inspection. It also exposes maintenance personnel to safety risks whilst inspecting. In addition to this, the detection of compromised joints is more challenging when assets are deenergized. The use of thermal imaging to detect temperature rise in a cooling joint can give unreliable results that are not indicative of the true state of a connection under load.

What are the human risks?

-1.png?width=24&height=24&name=Vector%20(2)-1.png)

To achieve a true operational likeness, inspections need to be performed whilst equipment is energized rather than de-energized due to connections cooling down. As personnel carry out inspections, actively seeking out problematic electrical joints, they become exposed to the potential safety risks resulting from loose connections.

Why choose Exertherm’s MCC solution

-1.png?width=24&height=24&name=Vector%20(2)-1.png)

Our patented MCC solution monitors 24x7, 365 days a year, and delivers 100% ‘always on’ uptime visibility for critical connections. The solution enables early detection of overheating joints, which are an early indicator of electrical component degradation.

The MCC solution is simple to install in new build or retrofit in existing equipment. The sensors operate as a standalone system, and use an algorithm to identify abnormal temperature rise before an electrical failure occurs. The solution also enables real time baseline data to be captured to provide trend analysis.

Permanently installed sensors remove the need for personnel to engage with energized equipment to carry out condition assessment, minimizing safety risks.

How do we justify Exertherm’s MCC solution to management?

-1.png?width=24&height=24&name=Vector%20(2)-1.png)

Traditional inspections typically require equipment shutdown to allow physical access, which can not only give unreliable results, but result in the inconvenience of downtime and lost productivity.

Our ‘fit-and-forget’ thermal sensors offer a smarter alternative:

- 24x7 real-time insights to help reduce unplanned downtime

- Compliant by design with key safety standards such as NFPA 70B

- No shutdowns - no recalibration - no ongoing maintenance

Our solution supports predictive maintenance planning, keeping your operations safe, efficient, and audit ready.

Why are all major OEMs shifting from periodic infrared inspections to continuous thermal monitoring?

-1.png?width=24&height=24&name=Vector%20(2)-1.png)

Because it works, continuously. Continuous Thermal Monitoring (CTM) provides always-on, real-time insights that periodic inspections simply can’t match. That’s why every major OEM now recommends it as the standard for predictive maintenance helping facilities reduce risk, improve uptime, and stay compliant.